An essential component of the global economy, laser cutting has grown prominent over several decades. Many industries may enjoy laser cutting, including manufacturing, medical, and more. Its products may be found all around the world. It would help if you tried out metal laser cutter.

Many features of laser cutting remain obscure to the general public. In what way does the mechanism work? Why does it have so many applications? When it comes to laser cutting, here are a few things to keep in mind:

This paper will cover all there is to know about laser cutting. There’s a lot to learn about laser cutters, from the very basics of how they work to all the many things you can do with them. Since technology is available to everyone, it’s a good thing. Let’s get the party started.

To begin, what exactly is laser cutting?

For the most part, laser cutting uses a laser to make physical changes to objects. Despite its futuristic appearance, laser cutting has been around for quite some time. As with many breakthroughs, its initial impact was modest, but it has been embraced enthusiastically by a wide range of industries. You can get better performance from sheet metal laser cutter.

Laser cutters may now be used with little difficulty. User interfaces have evolved intuitively, even though the technology itself is the product of genius. Many people use laser cutters for their projects and educational purposes. Also, a fantastic approach to learning about optics and light properties is via this usage.

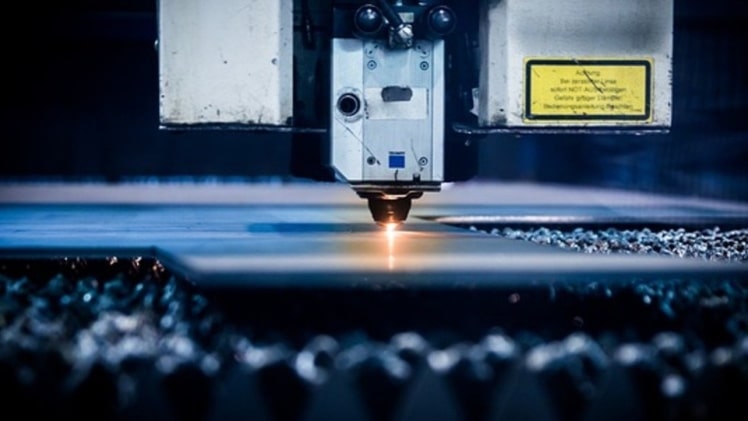

To cut with a laser, you first need a laser beam. To cut through metal, human flesh, or cardboard, the beam’s intensity must be adjusted until it is just suitable for the task at hand. The laser beam is directed to cut a specific pattern using a computer program. When the laser is activated, it will follow the pre-programmed course.

The laser beam moves and changes its focus length depending on the substance and the intended effect. As a result, it may reach varying depths and cut through various materials. Engraving and other metalworking methods may enjoy this. In contrast, because of its high level of precision, it may be used to cut medical equipment in a range of sectors, including medicine.

Using a laser to cut materials is an incredible advancement in technology. A place to find it is at the nexus of technological advancement and human interaction. There are now many uses for it, but as technology advances, more are predicted. To understand how a laser cutter works and its mechanics, let’s take a closer look at it.

This component creates the laser beam by focusing on a light beam with the same wavelength as the resonator. CO2 lasers produce an infrared beam, whereas other lasers use light with a different wavelength to do the same thing. About.75 percent of the time, it’s out “by the inch.

One or more mirrors reflect this beam of parallel light waves into the focusing head. Lenses are used to bring an object into focus after the beam enters the focusing head. After then, it’s released via a nozzle and starts consuming anything in its path.

What happens to the material when it is sliced with a laser??

Laser light collides with a surface, and what occurs next? Is there a way to control the cutting depth and consider various materials? The entry of compressed gas into the laser beams path was disregarded as a component of the laser system. As the beam approaches the focusing lens, it is joined by a jet of fast-moving gas, usually oxygen or nitrogen. Downhill, the gas shoots out of the nozzle, which also happens near a laser cutting.